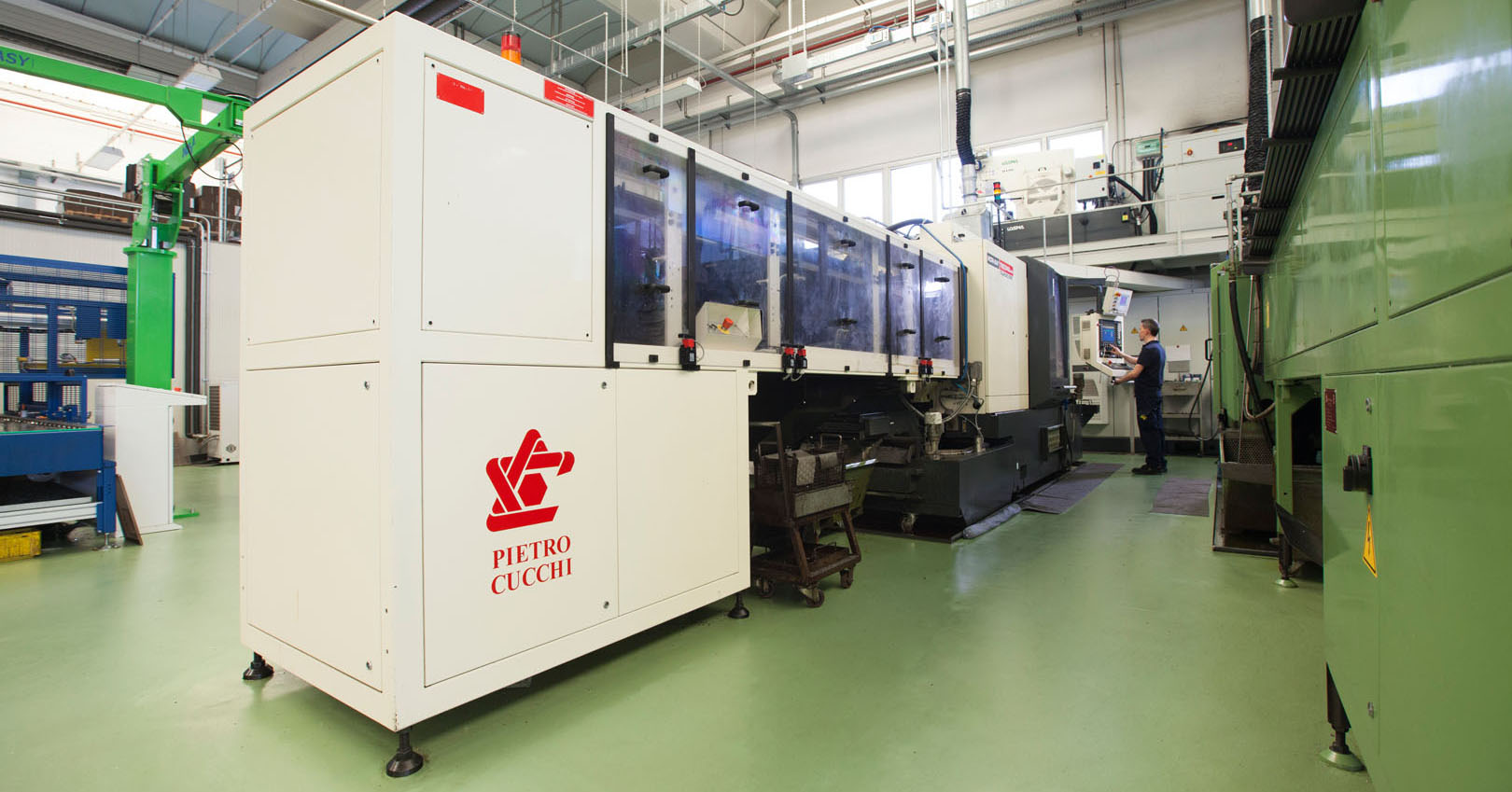

EXPERIENCE AND LATEST-GENERATION FACILITIES

Latest-generation facilities, our experience and the skills of our motivated colleagues enables us to make a wide range of components for use in all kinds of applications and in the most varied fields of use. Our story is tied to the automotive world, but the technologies and expertise at our disposal enable us to offer ourselves as reliable and qualified suppliers for any sector needing precision mechanical components.

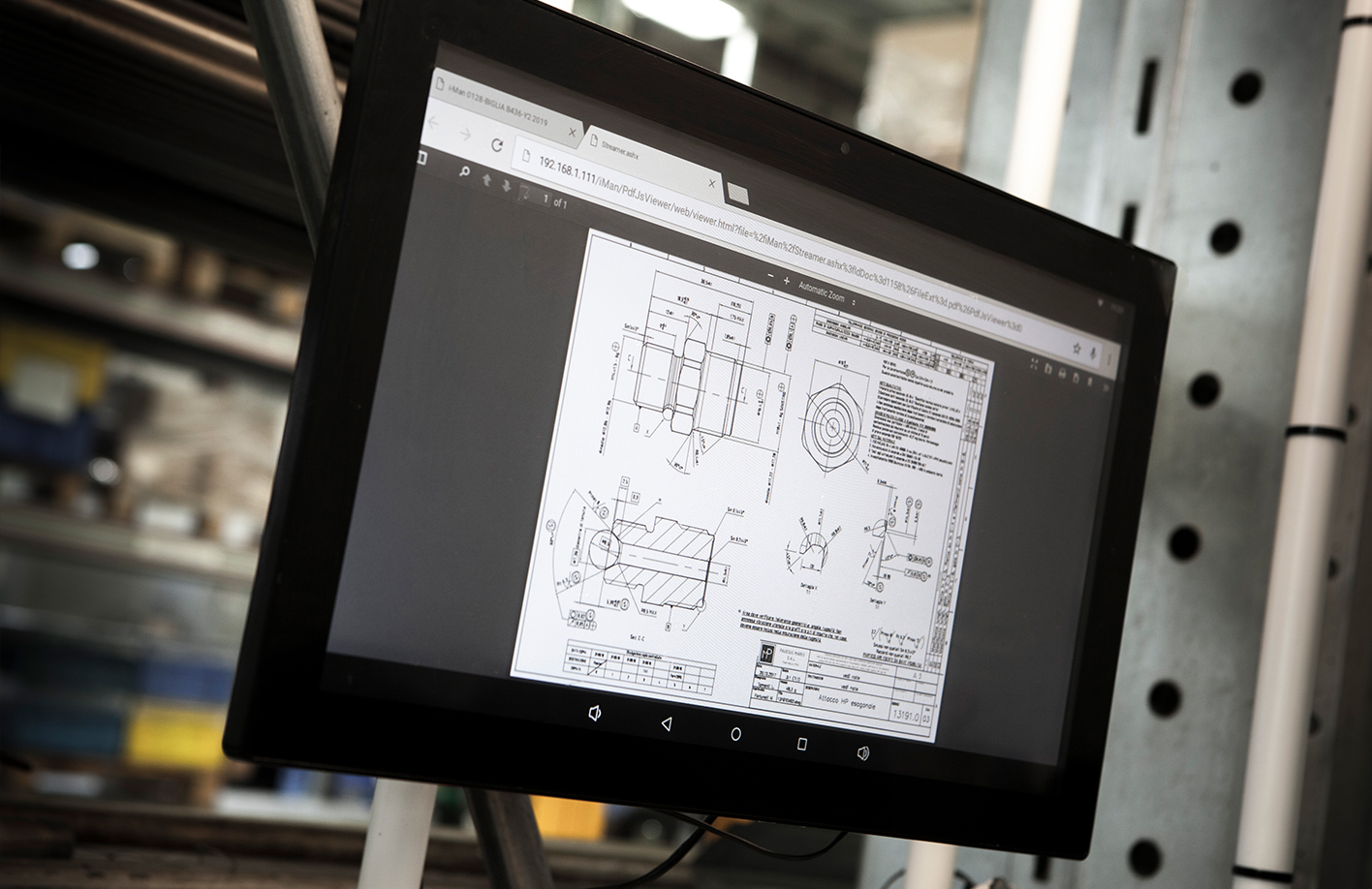

Our manufacturing process enables us to make all kinds of products and so we are always available for evaluating any design or project, putting any idea down on paper and checking the technical feasibility and economic viability.

From the simple turned part, to the most complex welded and folded assembled fittings, our range of products can be made in all the most common materials: automatic, high-resistance, case-hardened and stainless steels, as well as aluminum alloys and brass.

A reliable group of partner suppliers allows us to complete our products with different operations, ranging from grinding to milling, heat treatments to a wide range of galvanic treatments and finishing in general.

Ten years of technical experience acquired in the various types of processing combined with the use of innovative materials now enables us to provide products of extremely high quality for all kinds of applications in the automotive industry, such as fuel injectors, high-pressure fuel pumps, fuel filters, robotized gearboxes and high-pressure piping. Production is made to order, according to drawings and specifications provided by the customer, who can constantly count on the know-how and advise of our technical office for working out solutions that take the functional, technological and cost requirements of each product into account.

Numerical-control multi-spindle automatic lathes handling up to 42-mm bars

Mechanical multi-spindle (6/8 spindles) automatic lathes handling up to 42-mm bars

CNC sliding headstock automatic lathes handling up to 32-mm bars

CNC fixed headstock automatic lathes handling up to 65-mm bars

Six and eight-station transfer machines

Controlled-atmosphere brazing furnace

Proudly made in Piemonte

Proudly made in Piemonte